U Beam Production Line

Description:

To meet the increasing need of large steel structure bridge project, the manufacturing of U-stiffer unit is more and more important, for its large batch production and good welding quality. With years of experience in providing bridge-face manufacturing equipments, we have gain rich experience in manufacturing this U beam production line, so as to supply all kinds of corresponding lines for you.

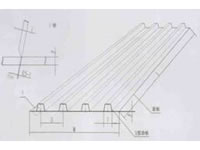

This U beam line consists of two steps as U-stiffer and panel maker. The bridge-face assembles structure as follows:

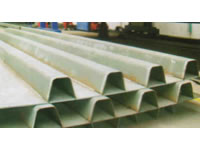

There two ways to manufacture U-stiffer described as roll-forming and bending forming. For the roll forming way, the slit coil is shaped gradually through roll forming machine, and planed, beveled, blunted at the same time. The advantage of this way is that it has high productivity. But investment is large, and there is still problem for wave-edge and asymmetry bevel is apt to appear, which means forming is not satisfactory. However, another way is to cut plate with plasma first, then bevel the plate, and bend it with large CNC press brake. Such method is low in cost and good effect.

The U stiffer production line include equipments such as, plasma cutting machine for plate, beveling of both sides of plate, forming of U beam, and drilling on U-stiffer, cutting the plate with plasma. It has advantage of good gloss, little side bend, reducing work volume greatly.

In the process of beveling of both sides of plate, the first thing is to mill the two vertical edge of plate with milling machine, guaranteeing accuracy of size. The second step is to bevel the plate with hobbing cutter.

The dedicated double side in-phase milling machine can mill the work-piece with thickness up to 160mm. Ten pieces of plates can be machined together in stacking manner, with width among 400 to 1000mm, length 18m. Each side of the work table has two milling unit, with milling power 7.5KW, efficient and economical.

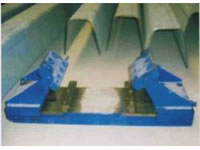

The joint of formed U-stiffener should be finished thru holes on it. For this reason, the U-stiffener should be fixed onto drilling fixture and drilled with the tool of radial driller. Upon finish of one side, the stiffener should be flipped to the side and drilled. It has high productivity and good accuracy.

The finished U-stiffener needs to be assembled into bridge-face assemblies. In this process, the U-stiffener assembly machine, U-stiffener multi-head welding machinery can be used for the purpose of automatic large volume production. To consider the effect of welding distortion, there are two kinds of technology for selection: one is to straightening with flame uniformly after assembly. The other is to take use of anti-distortion fixture post welding, which can achieve straightness of the work-piece.

The U-stiffer assembly equipment include: U-stiffer assembly machine, U-stiffer multi-head welding machine, U-stiffer Straightening machine.

The panel will be placed on the work-table and positioned against the positioning unit of the work table tightly. The U-stiffer will be positioned, pressed and tack-welded with reference to the pre-marked line on the panel, finishing assembly in this way. The machine has two types: pressing of ram is done with hand or hydraulic cylinder.

The assembled assembly will be secured on the overturning welding platform and welded. Taking advantage of the tracing unit, welding torch can follow the seam reliably. Machine gantry moves under welding speed; weld both sides of U-stiffer. On the basis of welding technology, welding process can be MIG or SAW. Welding platform is distortion-proof fixture, or flat work-table.

After welding, because of heat-input, U-stiffer will be distorted inevitably, so it should be flipped 180°straightening with fire.

By absorbing merits of similar U beam production line and using new technology from abroad and China domestic, Shanghai Salei is the professional producer to develop and manufacture the family U beam production line products including H-beam (light steel, heavy steel), box-beam production line, bridge-face U-stiffer welding production line, and steel structure cold roll forming production line as well as CNC waterjet cutting machine. With years development, Salei U beam production line have been spread over Saudi Arabia, Russia, Middle Asian, Southeast Asian, Australia, Europe, South American, North American, etc. Look forward to establishing mutually beneficial cooperation.

- Box Beam Production LineAs the development of steel structure market, box-beam will be used more an more widely in many fields like bridge, power station, boiler...

- H Beam Welding LineThe H beam production line consists of assembling machine, front welding machine, turn-over device, back welding machine and H beam...

English

English Español

Español Русский

Русский Português

Português